August 28, 2014

Battery Management System Scalability

When designing a battery management system, Nuvation’s fourth-generation battery management system and first off-the-shelf BMS, our goal was to create a set of modules that could be connected to the battery pack in different configurations to support a wide range of battery topologies with different chemistries, voltages, and capacities. Our industry research and consultations with customers revealed three main market verticals where such a configurable BMS was of greatest interest to manufacturers:

- Specialty Vehicles – Battery powered traction systems and subsystems

- Telecom Power Backup – Data centers and telecom towers

- Grid Energy Storage – Micro grid, solar, wind, etc.

While not every target battery deployment we encounter fits neatly into one of these categories, this matrix enables one to evaluate the Nuvation BMS in terms of its suitability to meet the full range of its target battery topologies.

Battery Pack Scalability

A battery pack is typically scaled in one or both of two directions: vertically and horizontally. Scaling vertically involves stacking battery cells in series to increase pack voltage. Scaling horizontally involves connecting multiple stacks of cells in parallel to create greater capacity at the same pack voltage. Very large systems usually require the pack to scale both vertically and horizontally to deliver high voltage and high capacity.

Returning to our matrix of battery pack configurations, we can summarize typical scalability needs as follows:

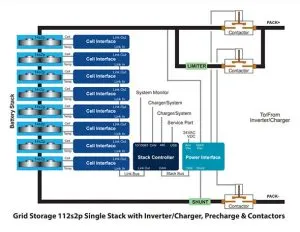

For each battery stack, Nuvation’s BMS has been partitioned into three distinct modules that are used as the building blocks of complete system.

- Stack Controller – performs all processing required to manage a single stack of cells

- Cell Interface – provides the electrical interface to a group of 12-16 battery cells

- Power Interface – powers the BMS, measures high voltages and large currents, and provides the electrical interface to high-current switching devices

- A Grid Battery Controller manages multiple stacks as a single unified battery’

Topologies

Separating functionality into these distinct modules allows Nuvation’s BMS to scale to support a wide range of topologies. Multiple Cell Interfaces are connected together in a daisy-chain that increases in height as pack voltage increases. This daisy-chain is connected to a single Stack Controller that manages all cells in the chain. Multiple Stack Controllers can be connected together to support large packs with many stacks in parallel. The Power Interface isolates high-voltage and high-current components of the stack physically and electrically from the other modules. It can also power the BMS directly from the battery stack, eliminating the need for any external power supplies.

Nuvation’s BMS is available in multiple variants that support a wide range of stack voltages. In future posts we will examine in more detail how we can use these three modules in various configurations to meet the voltage and capacity requirements of different pack topologies.